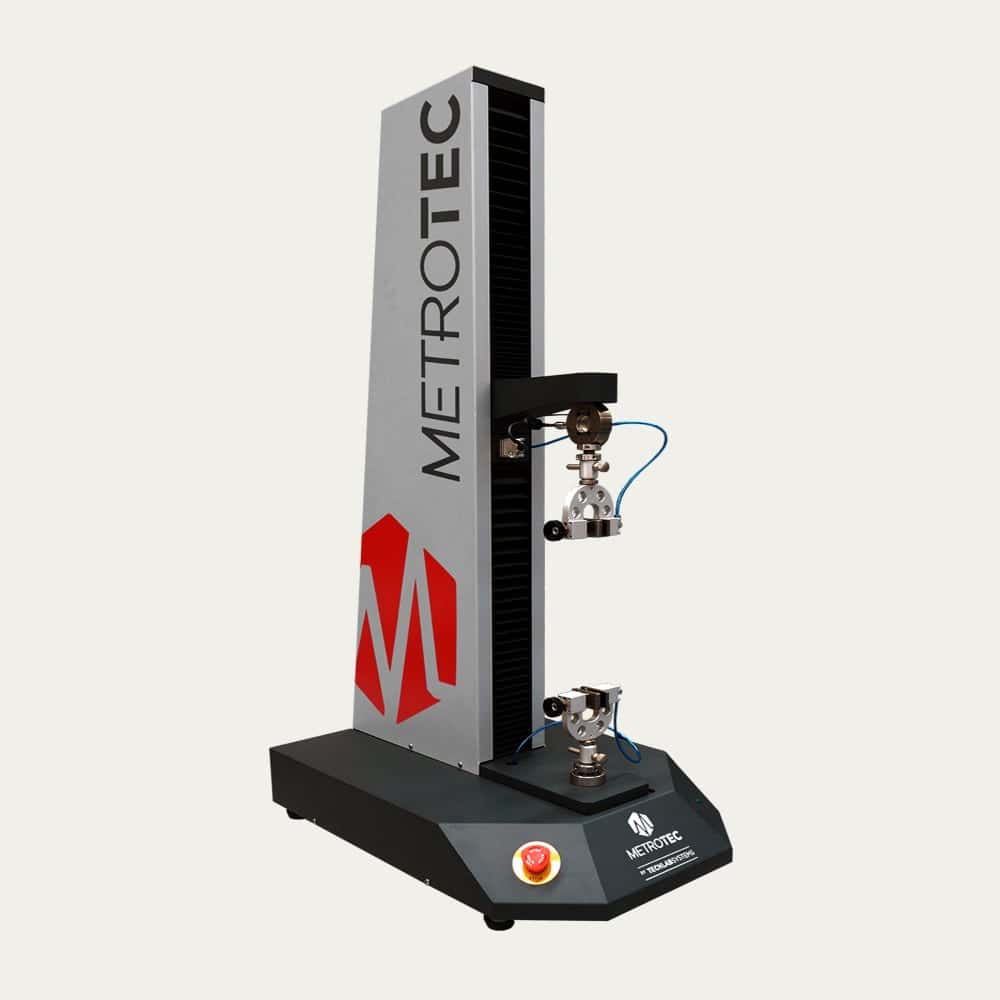

Charpy-Izod Notching Machine MNC-10

Description

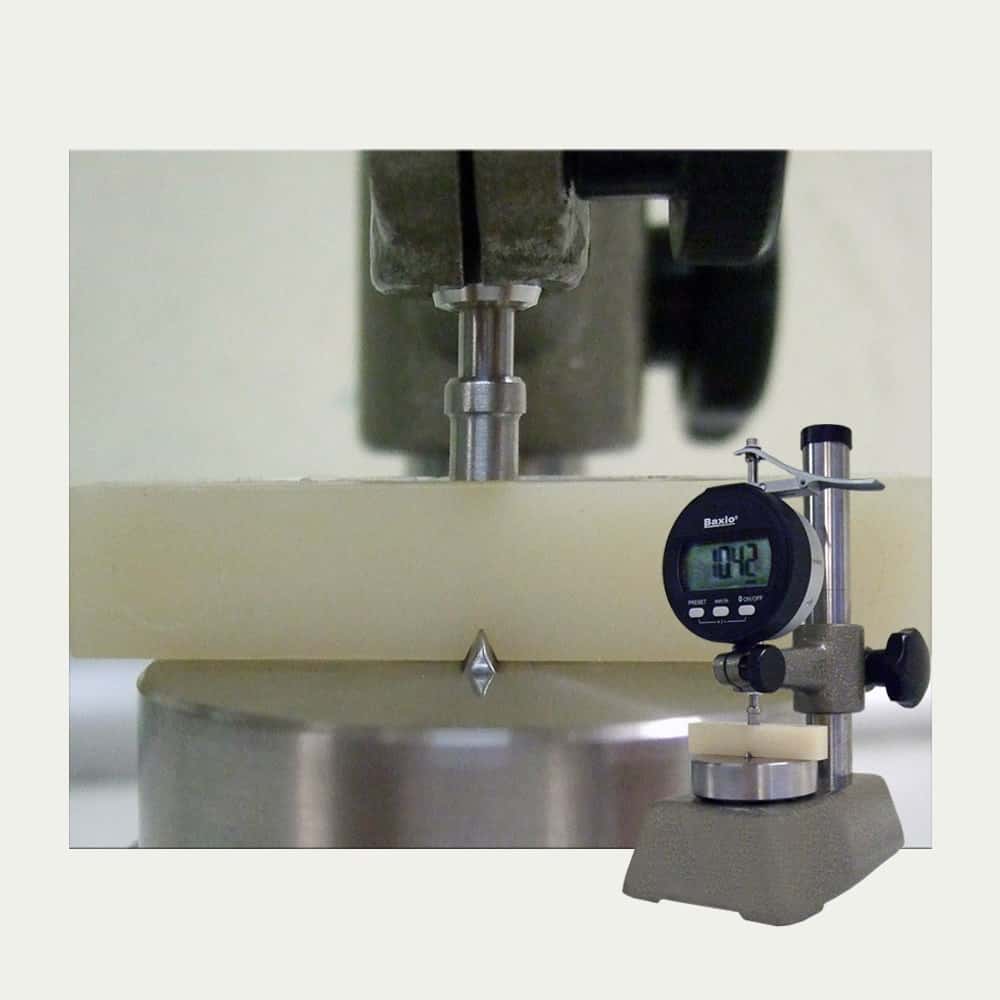

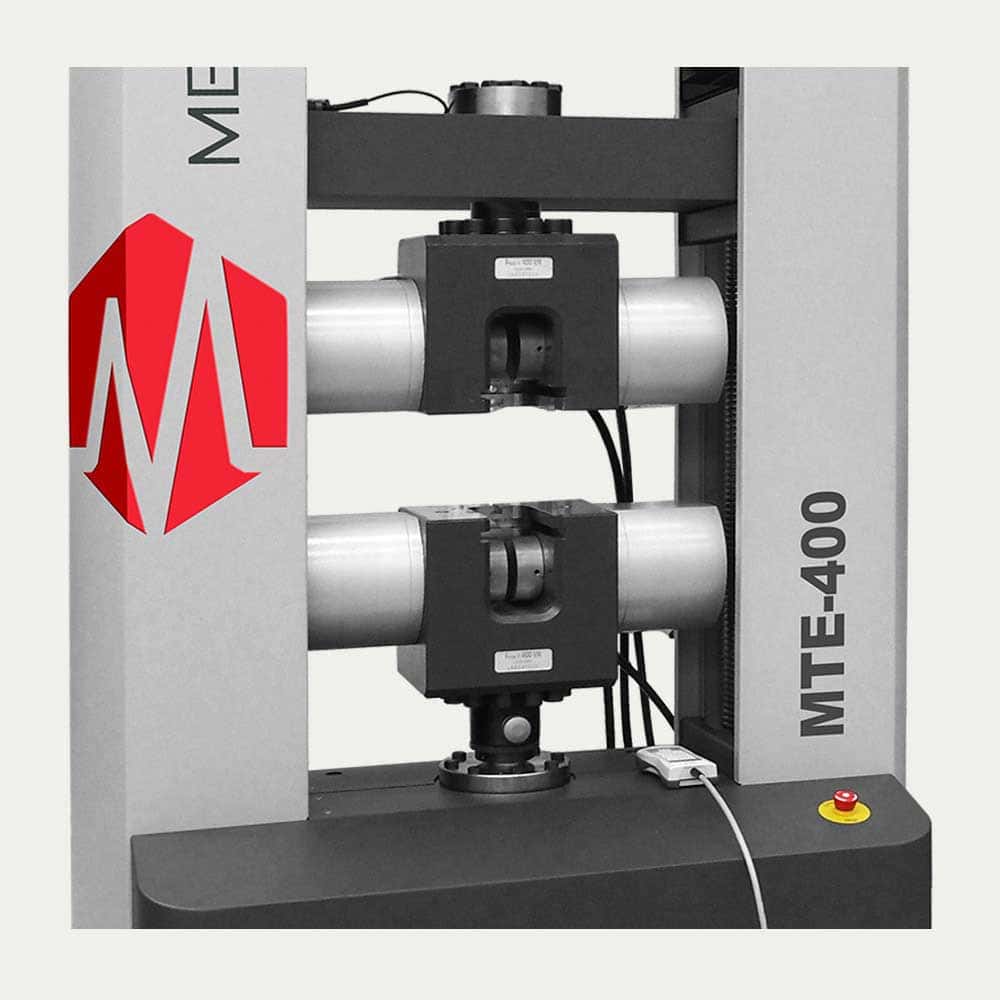

Equipment designed to make standardized notches on samples, which are subsequently subjected to mono-axial impact resistance tests, according to the CHARPY and IZOD procedures.

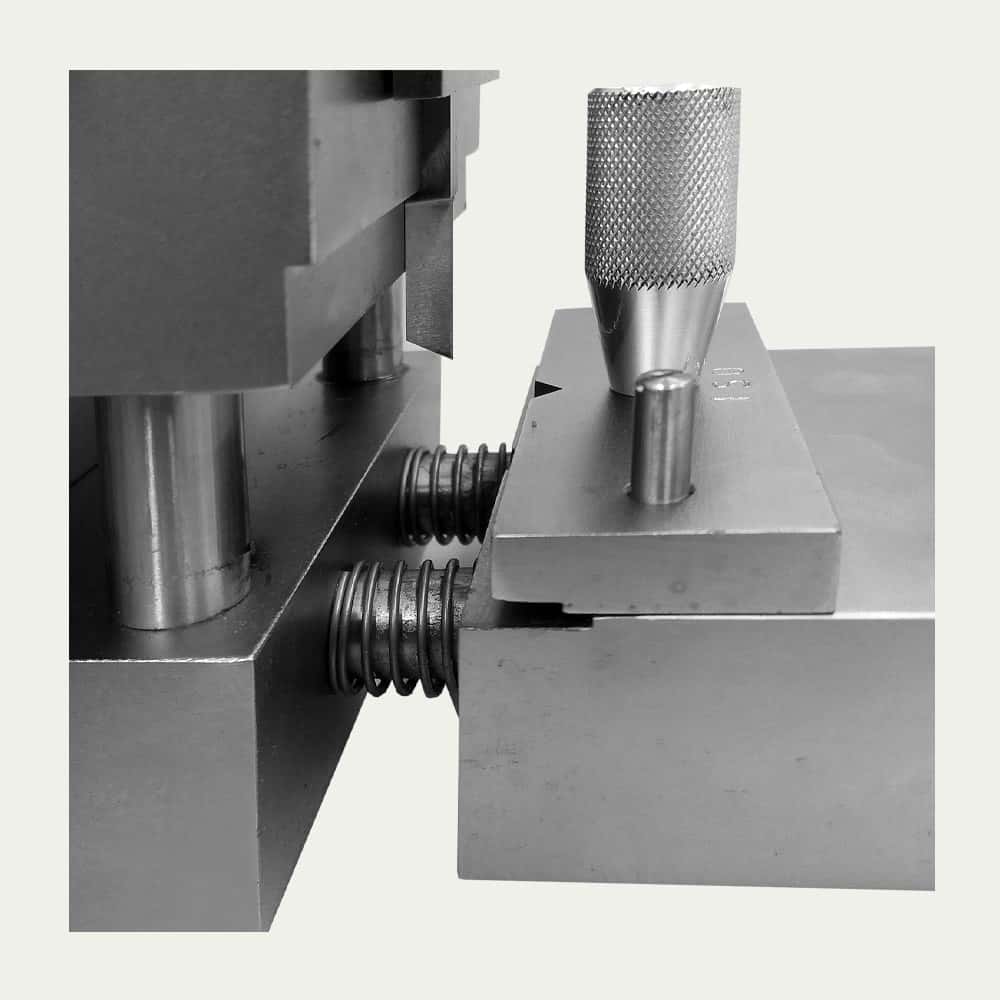

Includes 2 blades at a fixed angle of 45º ± 1º:

– 1 according to ASTM D 256 with a radius of 0.25 mm ± 0.01 mm.

– 1 according to ISO 179 / 180 to choose between:

- Type A with radius 0.25 mm ± 0.05 mm.

- Type B* with radius 1 mm ± 0.05 mm.

- Type C with 0.1mm ± 0.02mm radius.

- Analog Depth Micrometer 0-25mm with 0.01mm resolution.

- With variable speed to cover a wide range of materials: between 0 and 225 r.p.m.

- With protective safety screen.

- Blade oscillation speed: 0-225 r.p.m.

- Marcado CE

- Plastic urban furniture.

- Small household appliances .

- Plastic automotive parts .

- Plastic aeronautical parts.

ASTM D256/A, ASTM D256/B, ASTM D4812, ASTM D6110, DIN 179-1, DIN 180, EN 179-1, EN 180, ISO 179-1, ISO 180, UNE 179-1, UNE 180.